RETREADING RAISED

TO PERFECTION

RINGTREAD, a complete cold retreading system

that guarantees a perfect end result.

25%

of the European market share thanks to RINGTREAD

Thanks to RINGTREAD, more than 25% of cold retreaded tyres in Europe are produced through the use of Marangoni technology and this market share is growing. This is because it is the best technology for retreading that is nothing but advantageous: savings in terms of time, resources, and organization; top performance that only the spliceless ring can offer.

We make all the know-how of the Marangoni Group available to you, a group which has successfully made retreading its priority for more than 70 years.

RINGTREAD TESTIMONIALS

“The advantages of the tyres made in our plant using Ringtread technology were immediately clear, both to us and our customers, and indeed demand has grown constantly. Uniform processing and excellent values in terms of concentricity and balance mean that our product offers clear advantages over tyres made using traditional flat strips. Our mission is to offer our customers tyres that are absolutely reliable, guaranteeing the highest performance and reduced vehicle downtime, and consequently economic benefits. In this way, they don’t buy ‘just’ a retreaded tyre”

– Uwe Müller –

AD presso Reifen Müller GmbH – Hammelburg-Westheim

RINGTREADINGVS RETREADING

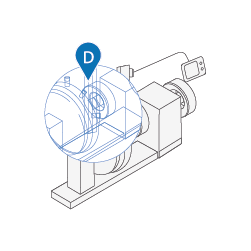

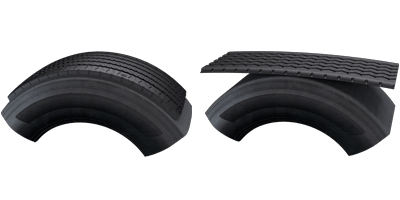

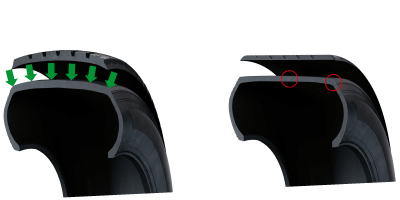

Each ring is produced individually by means of a centripetal radial press. Therefore, vulcanisation takes place in the final configuration of the tread, allowing the molecular structure to stabilise in a stress-free configuration.

no deformation = less wear

The strips are produced in long multi-stage presses, where it is difficult to precisely check temperature, pressure and vulcanisation times. The strip does not follow the convex shape of the casing: this deformation generates tension between the tread and the structure of the tyre, causing overheating.

The convex profile of the ring perfectly adapts to the curvature of the casing, preserving its integrity. Surface uniformity ensures maximum adhesion between the tread and the tyre structure as well as superior performance.

uniform tread = more kilometres

The application of a flat strip to the convex shape of the tyre structure causes deformation and weak points, which increase the tread wear rate and cause the casing to overheat, which could reduce the life of the tyre.

RINGTREAD allows for perfectly balanced retreaded tyres. The fact that they are spliceless reduces rolling resistance and ensures slow and regular wear, thus significantly reducing mileage costs and the total price of owning the tyre.

spliceless = maximum reliability

Retreading using conventional flat strips necessarily involves the presence of at least one splice. In addition to inevitably throwing the tyre off balance, this creates a weak point that can increase the likelihood of the thread detaching itself.

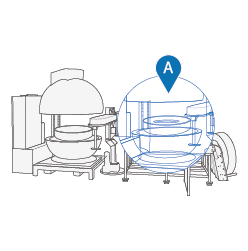

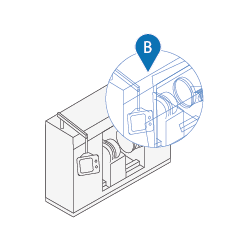

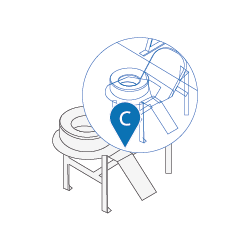

MACHINERY

Your best retread

Blackline is Marangoni’s response to the evolution the market has undergone in recent years, where fleets in particular have been demanding retreaded tyres, with reliable performance, improved durability and rolling resistance which is comparable or superior to quality new tyres in order to guarantee much needed savings.

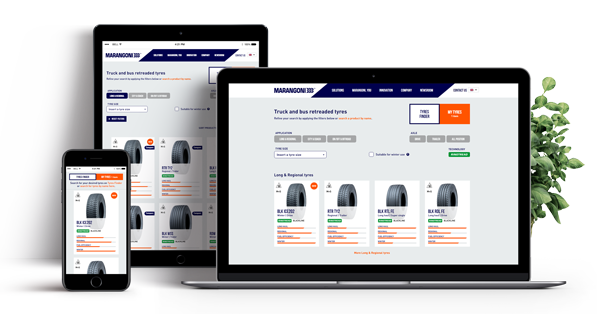

The Tyres Finder is a valuable guide to better orient both fleets and retreaders. It offers a broad and always up-to-date overview of options for a properly informed choice of products that best meet their needs.

For the end-user, the tool illustrates the range of retreaded tyres that can be manufactured with Marangoni‘s materials. The retreader will also find the needed technical information about rings and treads, just a click away.